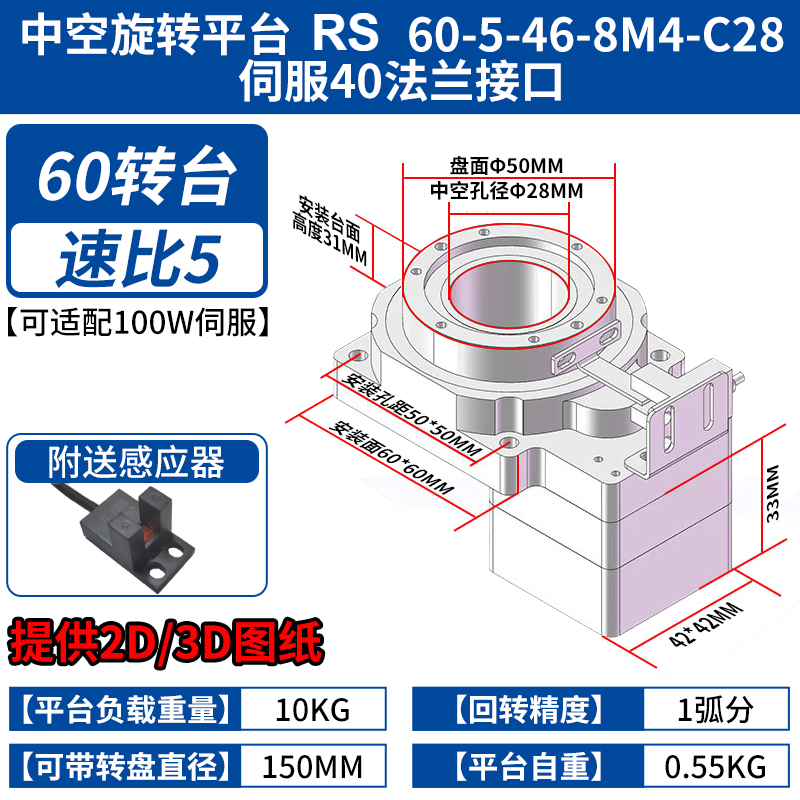

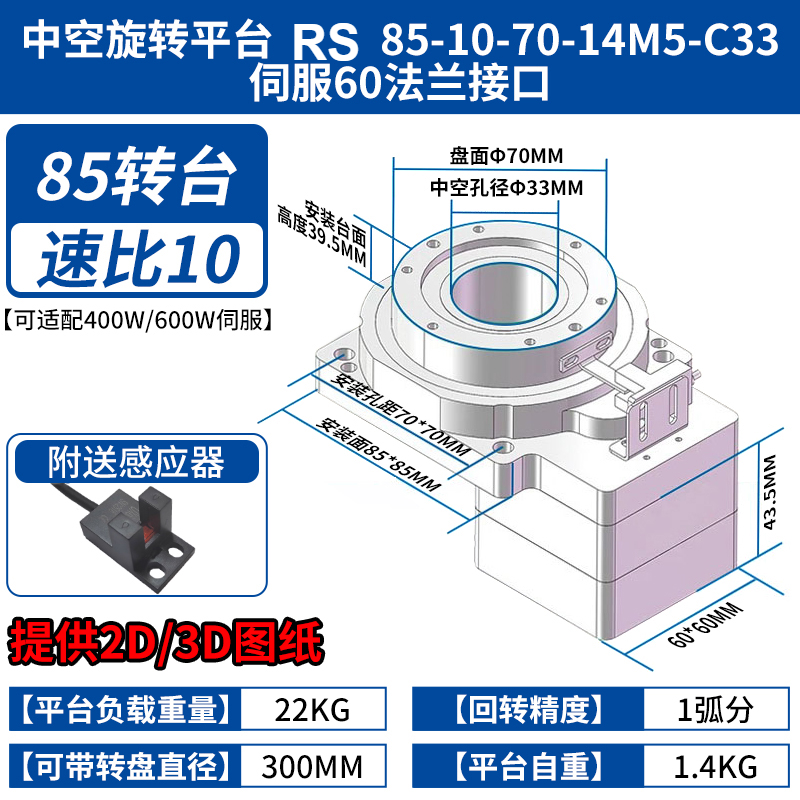

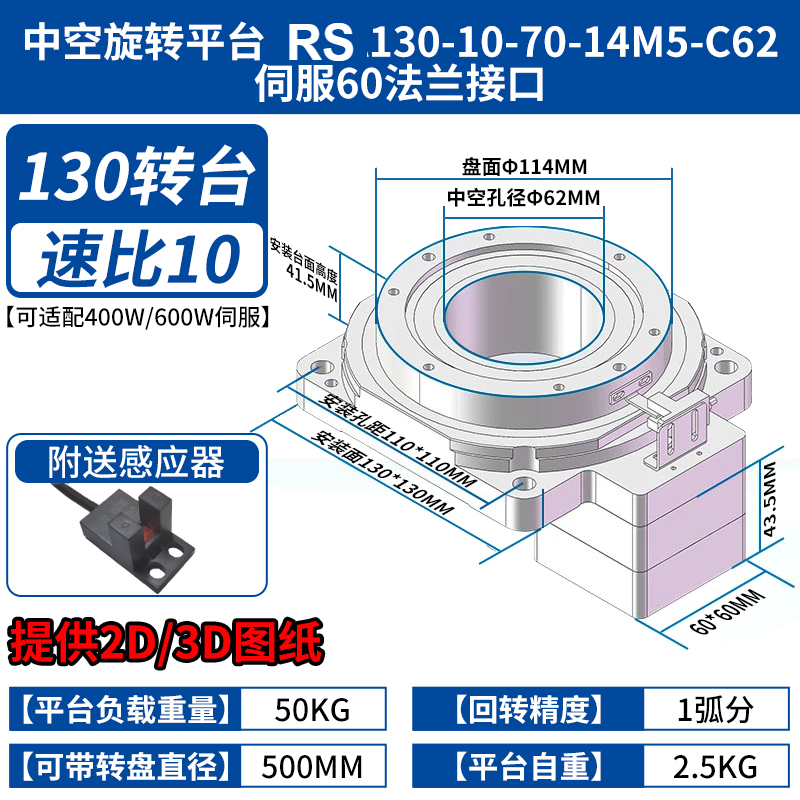

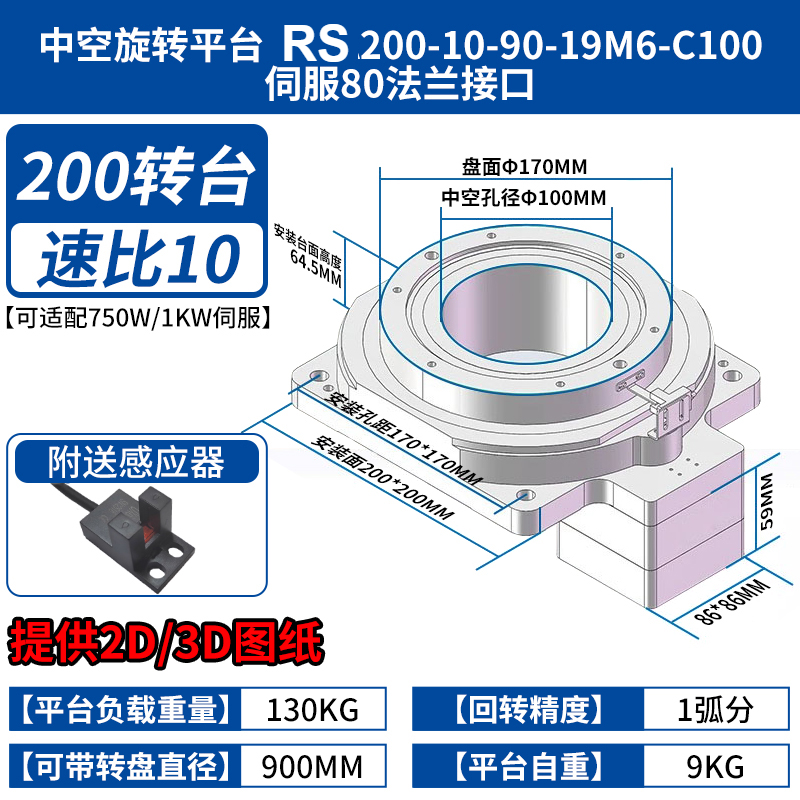

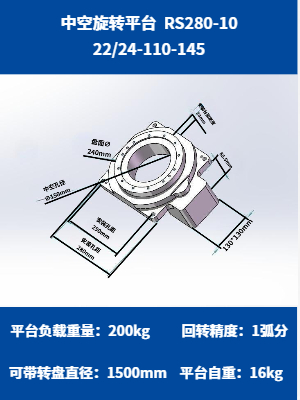

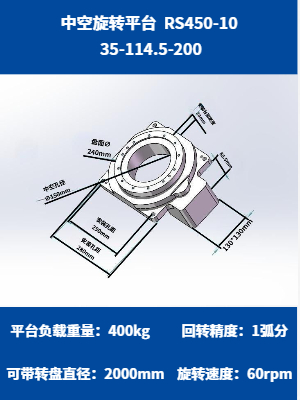

The hollow rotary platform combines high transmission efficiency, high precision, high rigidity, and high cost-effectiveness, integrating the advantages of servo motors, cam dividers, and direct-drive motors. Utilizing a high-precision helical gear structure and cross bearings, it improves torque, rigidity, and handles heavy radial forces. When paired with servo or stepper motors, it can perform arbitrary angle division and precise positioning, satisfying the limitations of dividers in achieving bit control while maintaining positioning accuracy comparable to direct-drive motors, enabling positioning of inertial loads in a short time.

🎯 Core technology highlights

30 arcsecond backlash • Large-diameter hollow output platform • High strength • Integrated structure that shortens equipment start-up time • Motor direction selectable according to space • Installation direction selectable.

The RS series (85, 130, 230, 280, 450) uses crossed roller bearings to ensure smooth rotation and precise positioning of the rotary platform, and provides high rigidity and axial and radial load capacity.